Why Polyaspartic Garage Floor Coating is 10X Better Than Epoxy

Deciding between a polyaspartic garage floor coating and an epoxy coating is a big decision for any homeowner. You’re looking at that stained, dusty, or cracked concrete in your garage, and you know it’s time for an upgrade. For years, the only answer you ever heard about was epoxy. It seemed like a good idea, but you’ve probably seen what happens to those floors after just a few years. They start to peel up, turn yellow, and look worse than the concrete underneath.

We’re Floortek Coatings, and we’re here to tell you there’s a much, much better way. As professionals who fix failing garage floors across the United States every single week, we’ve seen the problems with epoxy firsthand. We’ve also seen the long-lasting, durable solution that makes homeowners happy for decades.

That solution is a polyaspartic floor coating.

We believe in this technology so much that we've built our entire business around it. It’s the only system we trust to install in our customers’ homes. And to prove it to you, we’re offering 30% off on your first installation. It’s time to learn the truth about the polyaspartic vs epoxy garage floor debate and see why one is a temporary fix and the other is a permanent solution.

The Real Story: Why Epoxy Floors Fail

Before we talk about the solution, let’s be honest about the problem. Why does that neighbor’s DIY epoxy floor look so terrible? The issue with epoxy is that it’s an old technology. It was a good step up from plain paint, but it has several significant flaws that don’t stand up to the reality of a modern garage.

The Peeling Nightmare: Hot-Tire Pickup

This is the number one complaint we hear. A homeowner pulls their car into the garage after driving, especially on a hot summer day. Those tires are hot—really hot. Epoxy is basically a hard, rigid plastic shell. When that hot tire sits on it, the heat softens the epoxy. Then, as the tire cools, it contracts and literally "picks up" the coating, pulling it right off the concrete.

You’re left with bare, ugly spots that look like a bad sunburn peeling. This isn't a defect; it's just how epoxy reacts to heat. In southern and western states with intense heat, this can happen in less than a year. Once it starts, it’s impossible to stop without a complete removal (and the cost). This is a key factor when considering polyaspartic garage floor coating vs epoxy.

The Yellowing Problem

Epoxy is not UV stable. In plain English, sunlight makes it turn yellow. Most epoxy coatings are "aromatic," a technical term meaning they break down under ultraviolet (UV) light.

Does your garage door have windows? Do you ever leave your garage door open on a nice day? That sunlight hits the floor and, over time, will turn that clean gray or tan floor into a sickly, dirty-looking yellow. It doesn't matter how well you clean it; the color change is permanent. It makes the floor look old and dirty, even when it’s brand new. This is a massive letdown for homeowners who wanted a bright, clean space.

The Week-Long Installation

Another major headache with epoxy is the time required to install it. The process is slow and fussy. First, you have to prep the floor (which most DIY kits get wrong). Then you apply a primer. You wait a day. Then you use the epoxy color coat. You wait another day. Then you use a topcoat (if you have one). You wait another day.

After all that, you still can’t park on it. Most epoxy systems require you to stay off the floor completely for 24-48 hours and wait as long as 5-7 days before you can park your car on it. Your garage—and everything in it—is held hostage for an entire week. If the temperature or humidity isn’t perfect during that week, the coating can fail before you even use it.

We get asked all the time, How long does epoxy last? The truth is, even when installed perfectly, it’s a temporary solution that’s prone to failure. That’s why we only use polyaspartic technology.

What is a Polyaspartic Coating, Anyway?

So, what is this "new" technology? Polyaspartic coatings are a type of polyurea. If you’ve ever heard of polyurea coating for a garage floor, a polyaspartic is an advanced, specialized version of it. You can learn more about what a polyurea concrete coating is on our blog, but here’s the simple version.

This technology was initially developed for heavy-duty industrial uses: think bridges, wastewater treatment plants, and factories. It was designed to protect concrete from harsh chemicals and extreme weather. It had to be rigid, flexible, and apply quickly so these critical areas could get back to service.

For years, this technology was too expensive for home use. But thanks to advances in science, we can now bring this industrial-strength protection to your home.

Unlike epoxy, which sits on top of the concrete, a polyaspartic garage floor system is designed to soak in and chemically bond with the concrete itself. It becomes a part of the concrete, not just a layer of paint on top. This one difference is the answer to the question: Is polyaspartic better than epoxy? Yes. It is 10X better, providing you with a durable, long-lasting solution that you can be confident in.

The Head-to-Head Battle: Polyaspartic Garage Floor Coating vs Epoxy

When you put the two materials side by side, the differences are apparent. This isn't just a slight upgrade; it's a whole new level of quality and performance.

Advantage #1: Get Your Garage Back in ONE Day

Let’s start with the biggest one: your time. That week-long epoxy installation we talked about? Forget it.

Our polyaspartic system is the core of our 1-day garage floor coating promise. We don’t mean "we start it in one day." We mean we are finished in one day, ensuring your comfort and convenience throughout the installation process.

Morning: Our team arrives and begins the most crucial step: diamond-grinding the concrete (more on that later).

Late Morning: We apply our deep-wicking polyaspartic base coat.

Mid-day: We broadcast your chosen chip flake blend across the entire floor.

Afternoon: We scrape the floor to perfection and apply our 100% clear, UV-stable polyaspartic topcoat.

Evening: By the time we leave, you can walk on your new floor.

Next Day: You can park your car and move everything back in.

In just 24 hours, you go from a cracked, ugly floor to a beautiful, finished, and fully usable space. With epoxy, you’d still be waiting for the first coat of primer to dry. For busy families and homeowners in the US who can't afford to lose their garage for a week, this is the only choice.

Advantage #2: A Floor That Bends, Not Breaks (Goodbye, Hot-Tire Pickup)

Remember how epoxy is a hard, brittle shell? Polyaspartic is the opposite. It’s incredibly durable but also flexible. This is a game-changer for a few reasons.

First, concrete naturally expands and contracts with changes in temperature. In the cold winters, it shrinks. In the hot summers, it expands. A rigid epoxy floor can’t handle this movement, so it cracks and delaminates. Our polyaspartic garage floor coating is flexible, so it moves with your concrete. No cracking, no peeling.

Second, this flexibility is the ultimate weapon against hot-tire pickup. When you pull your hot car onto our floor, the polyaspartic coating can handle the heat without softening. It has a much higher heat tolerance than epoxy. The bond isn’t compromised, the coating doesn't budge, and your floor stays exactly where it’s supposed to be.

Advantage #3: It Won't Yellow. Ever.

This is a simple one. Polyaspartic coatings are "aliphatic." That’s the technical term for "100% UV stable."

You can leave your garage door open all day, every day, even in the most intense sunshine in states like Arizona, Texas, or Florida. Your floor will look the same color five, ten, or twenty years from now as it did the day we installed it.

That bright, clean gray will stay gray. That beautiful tan will stay tan. When you’re comparing polyaspartic garage floor coating vs epoxy, the fact that one will always turn yellow and the other will not is a major deciding factor. Why invest in a new floor to watch it fade and discolor?

Advantage #4: Superior Protection From Salt, Oil, and More

Your garage isn't a clean room. It’s where you work. Cars leak oil, gas, and antifreeze. In the winter, your tires track in corrosive road salt and de-icing chemicals.

Epoxy is porous and can be stained or damaged by these chemicals. A gas or oil spill can leave a permanent dark spot, and road salt can slowly eat away at the finish.

Polyaspartic coatings are non-porous and incredibly resistant to chemicals. Gas, oil, brake fluid, salt, bleach—you name it, it just wipes right off. Nothing penetrates the surface. This means your floor is not only protected, but it’s also incredibly easy to clean. A little soap and water, or just a quick pass with a hose, is all it takes to make it look brand new again.

Advantage #5: We Can Install It (Almost) Any Time of Year

Epoxy is a princess. It needs the weather to be just right. It can’t be installed if the temperature is below 55°F or the humidity is too high. This severely limits the installation window for most of the United States.

Our polyaspartic system is a workhorse. It can be applied at temperatures from -30°F to 140°F.

This means we can install your floor during a mild Ohio spring, a blazing Texas summer, or even a frigid Minnesota winter. The material is designed to cure perfectly in almost any condition. You don’t have to wait for the "perfect day" to get your perfect floor. We work on your schedule, not the weather’s.

Why You Can't Get This From a DIY Kit

This is a critical point we need to make. You will see "1-part epoxy" or "epoxy-in-a-box" kits at the big-box hardware stores. These are not even in the same league as a professional epoxy job, let alone our polyaspartic system.

The number one reason for any coating failure is improper prep. Those DIY kits tell you to "acid etch" the floor. This is a weak, unreliable method that roughens the very top layer. It doesn't open up the concrete's pores.

At Floortek, we follow a strict process. You can read a complete guide on How To Prepare Your Floor For A New Polyaspartic Concrete Coating, but the most crucial part is this: we use industrial-grade diamond grinders.

This isn't a sander. This is a massive machine that grinds off the weak top layer of your concrete, removes all stains and sealers, and opens up the pores. This creates a "concrete profile" that our base coat can grab onto, wicking deep into the concrete to create an unbreakable bond.

A DIY kit on a poorly prepped floor will peel in months. Our system, bonded to professionally ground concrete, is designed to last for decades. This is why we can confidently offer a Life-of-home warranty on our floors. The polyaspartic garage floor coating vs. epoxy debate isn't just about materials; it's about the professional process that ensures they last.

Take the Floortek Protection to Your Whole Home

That same industrial-strength protection isn't just for your garage. The benefits of a polyaspartic coating—its UV stability, durability, and ease of cleaning—make it the perfect choice for so many other areas of your home.

Imagine that beautiful, seamless finish on your...

Patio: Our patio coating service is ideal for outdoor spaces because it won't fade or yellow in direct sunlight.

Pool Deck: Get a beautiful, durable surface with our pool deck coating service.

Driveway: Stop worrying about salt and stains. Our driveway coating service gives you instant curb appeal that lasts.

Basement: Our Basement coating service creates a clean, bright, and finished look for your downstairs living space.

Sidewalks: Protect your walkways with our sidewalk coating service.

Other Spaces: We can also coat laundry rooms and commercial spaces.

Anywhere you have ugly concrete, we have a beautiful, permanent solution.

Our Promise: A Floor That Lasts

When you choose Floortek, you're not just buying a product; you're investing in a professional service from a team that cares about quality. You can learn more about us and our commitment to our customers.

We don't believe in "good enough." We believe in giving you the best.

The Best Look: We offer a vast range of Colors and Flake Options to match your home's style perfectly. You can find inspiration in our blog on Colors and Flake Options.

The Best Materials: We only use top-of-the-line polyaspartic and polyurea systems. Learn about Our Coating Products to see what sets them apart.

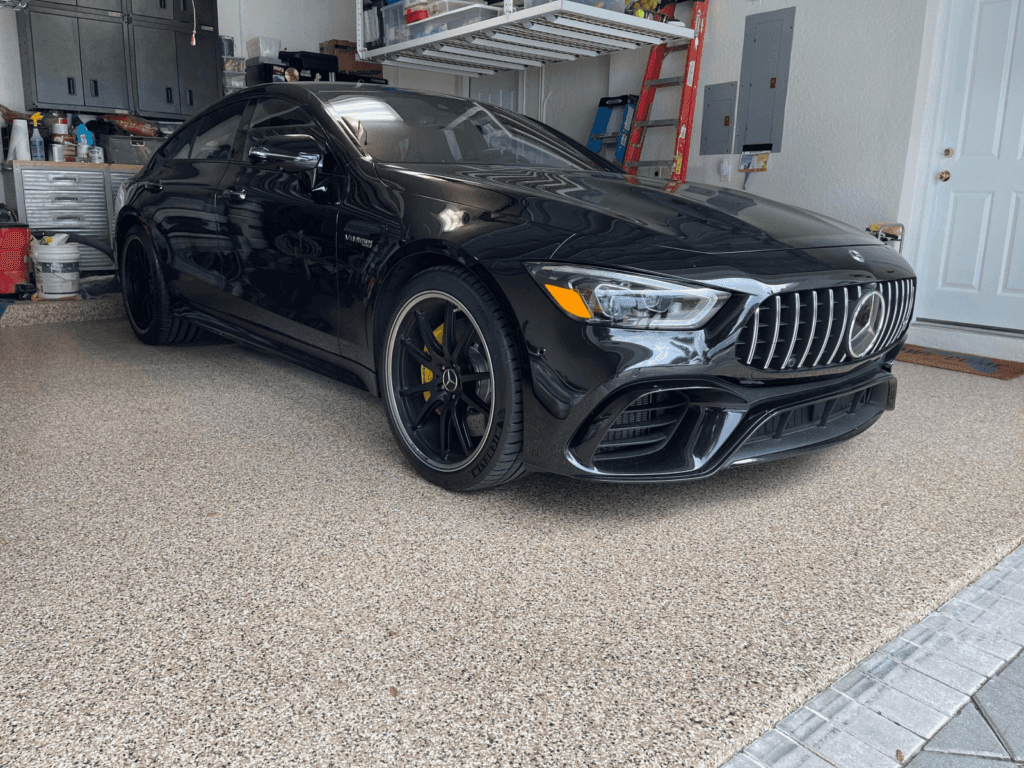

The Best Proof: You don't have to take our word for it. You can see hundreds of our completed projects in our Gallery.

The Best Warranty: We stand behind our work with a Life-of-home warranty that gives you total peace of mind.

The discussion over the polyurea vs. epoxy debate regarding coating life expectancy is settled. One is a gamble, and the other is a guarantee. When you see our system, you'll know which garage floor coating is the best on the market.

Your Questions About Polyaspartic vs. Epoxy, Answered

We get a lot of questions from homeowners. Here are the answers to the most common ones.

1. What is the main difference between polyaspartic and epoxy?

The main difference is the chemistry. Epoxy is a rigid, plastic-like coating that sits on top of the concrete and takes days to cure. Polyaspartic is a flexible, more durable material that soaks into the concrete, bonds with it, and cures in just one day.

2. Is polyaspartic garage floor coating really better than epoxy?

Yes, in almost every way. It's more durable, it's flexible so it won't peel from hot tires, it's 100% UV stable so it won't turn yellow, and it can be installed in just one day, any time of year.

3. How long does a polyaspartic floor take to install?

Our professional Floortek team can install most standard garage floors in just one day. You can walk on it in 4-6 hours, and park your car on it for 24 hours.

4. Will a polyaspartic garage floor peel like epoxy?

No. When appropriately installed with our diamond-grinding preparation, a polyaspartic floor forms a permanent chemical bond with the concrete. Its flexibility and high heat tolerance prevent hot-tire pickup, which causes epoxy to peel.

5. Is polyaspartic the same as polyurea?

They are related! A polyaspartic is a specific type of polyurea. Think of polyurea as the "family" and polyaspartic as the high-performance member of that family. It's been modified to be more workable for floor coatings and to be 100% UV-stable.

6. I see DIY polyaspartic kits. Are those any good?

We strongly advise against them. Polyaspartic material cures extremely fast—sometimes in minutes. It requires a professional, experienced team to apply it correctly. More importantly, those kits still don't come with the industrial diamond grinder needed for proper prep, so they will likely fail just as epoxy kits do.

7. Can you put a polyaspartic topcoat over epoxy?

Some companies do this as a "hybrid" system. We don't. The problem is that you still have a weak epoxy base coat. When that epoxy base fails (which it will), it will take the expensive polyaspartic topcoat with it. We believe in doing it right the first time with a complete polyaspartic system from the concrete up.

8. Is the floor easy to clean?

Incredibly easy. Because it's non-porous and chemical-resistant, almost nothing can stain it. Dirt, mud, oil, and salt all wipe right off, leaving the floor looking brand new.

9. What about road salt in the winter?

Polyaspartic coatings are perfect for cold-weather climates. They are 100% resistant to road salt and de-icing brines that can destroy concrete and stain epoxy.

10. Why is this better than just painting or sealing my garage?

Paint is a temporary fix that will peel from hot tires in a matter of weeks. A "sealer" is a clear, thin coat that offers almost no protection. A polyaspartic system is a thick, industrial-grade coating that completely resurfaces your concrete, protecting it for decades. It's not just a garage resurfacing epoxy fix; it's a permanent upgrade.

Make the Right Choice for Your Home

The choice in the polyaspartic garage floor coating vs epoxy debate is clear. Epoxy is an outdated, temporary fix that will lead to peeling, yellowing, and frustration.

A Floortek polyaspartic coating system is a modern, permanent solution. It's the only choice for a homeowner who values quality, durability, and their own time. It's the only floor that can be installed in one day, won't yellow from the sun, and won't peel from hot tires. That's why we back it with our Life-of-home warranty.

Stop staring at that ugly concrete. Stop thinking about a DIY kit that will fail in a year. It's time to get the floor your home deserves.

Take the first step today. We’re offering a 30% Off promotion for all first-time installations.

Contact us through our website to schedule your Free Quote, or call us right now at 844-844-4164 to speak with a Floortek specialist in your area. Let us show you the Floortek difference.

External Resource References:

US Department of Transportation - Information on advanced polymers used in infrastructure.

Purdue University - Research on polymer concrete properties and applications.

FREE In-Home Estimate

Plus 30% Off

Testimonials

We had both of our garages done and an outdoor concrete platform. The crew was courteous and professional. Everyone from Nancy our salesperson to Patrick, the manager, Logan and his crew were outstanding. Our floors look fantastic and we were very happy we chose this company.

I am very pleased with the quality of work FloorTek has done for me. The two employees that did the actual work were very courteous, worked hard, and explained everything they were doing. Thank you for a great job.

I was happy with the job Floortek did. Good customer communication and customer relationship. My old ugly porch was transformed and I love it. Nancy was very helpful throughout the process. Just know that rain may impact your schedule to make sure the products at highest quality during application.

Contact FloorTek Today